Magnets are the essential components of loudspeakers, compact disc players, electric motors, computers, family car, production equipment, instrumentation and many other things of daily life. As these are built in devices, most of us overlook their contribution. The main function of these magnets is to transform energy from one place to another without losing their energy. Here are few categories of the permanent magnet-

- Mechanical to electrical – microphones, generators and magnetos fall under this category

- Mechanical to mechanical – they are found in the magnetic torque drivers, holding devices, separators, magnetic bearing and so on.

- Electrical to mechanical – examples of such objects are actuators, relays, motors, loudspeakers, meters, ion pumps, traveling wave tubes etc.

- Special effects – they are found in hall affect devices, magneto resistance and magnetic resonance

The common commercialized magnets

Broadly, four classes of modern commercialized magnets are available in the market depending on their composition. There classes are alnico, samarium cobalt, ferrite, neodymium boron etc. The neodymium iron boron has been recently added to the group of modern materials. When kept at the room temperature, they show maximum properties of magnet materials.

What you must know while purchasing them?

These magnets have different properties and wide variety of applications. You have to consider various factors like shape, material, grade, size of magnet and many others while making the purchase.

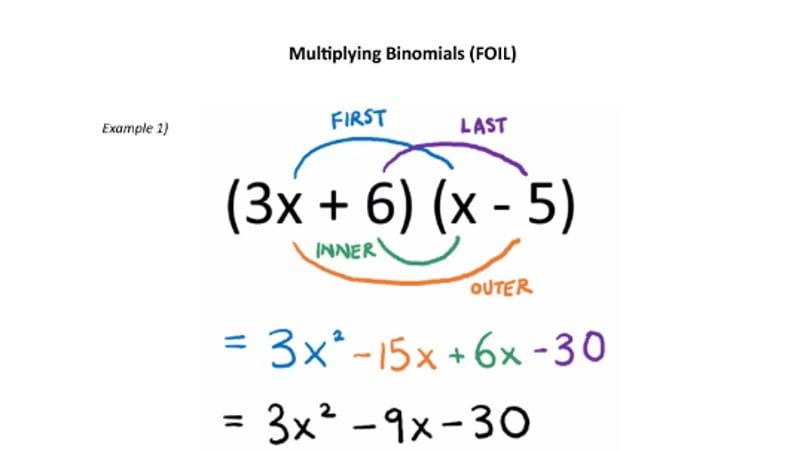

While designing the magnets, experts consider the popular B-H curve. This curve is also known as the hysteresis loop. The curve determines how a magnet will behave when it is demagnetized, brought to the saturation point, it is saturated in opposite direction and much more.

Second quadrant of the curve will help to study the demagnetization curve. There are three important points in the curve where B axis intersects with H axis. Magnet is able to produce the maximum flux of Br. It becomes demagnetized at the point Hc.

Here are some factors that will affect the magnetic stability-

- Temperature

- Time

- Reversible losses

- Irreversible and Unrecoverable losses

- Irreversible but recoverable losses

- Adverse fields

- Reluctance changes

- Shock, stress and vibration

- Radiation

There is a minimum impact of time of any permanent magnet. According to the studies, magnets will observe immediate changes after magnetization. These changes are also known as magnetic creep. As the rare earth magnets have high coercivities, they will not experience any effect of time.

The magnets easily recover reversible losses as soon as they return to original temperature. Even the magnet stabilization could not eliminate reversible losses.

Learn about the manufacturing process

Different methods are used to manufacture these magnets depending on their type. While purchasing them, you have to check what stores sell neodymium magnets, how to manufacture them etc.

The flexible and bonded neodymium is prepared using the unique technique extruding. Calendaring is used to prepare flexible magnets. The injection molding and pressure bonding is the best technique to manufacture ferrites and rare earth magnets. During the sintering process, the fine powders of magnets are compacted together at high pressure in order to fuse in solid shape.